The recent

Maker Faire provided our Maker Club an opportunity to meet and collaborate with the leading 3D Printer manufacturers in the world. We saw this as an opportunity to test their print quality on a hard challenge.

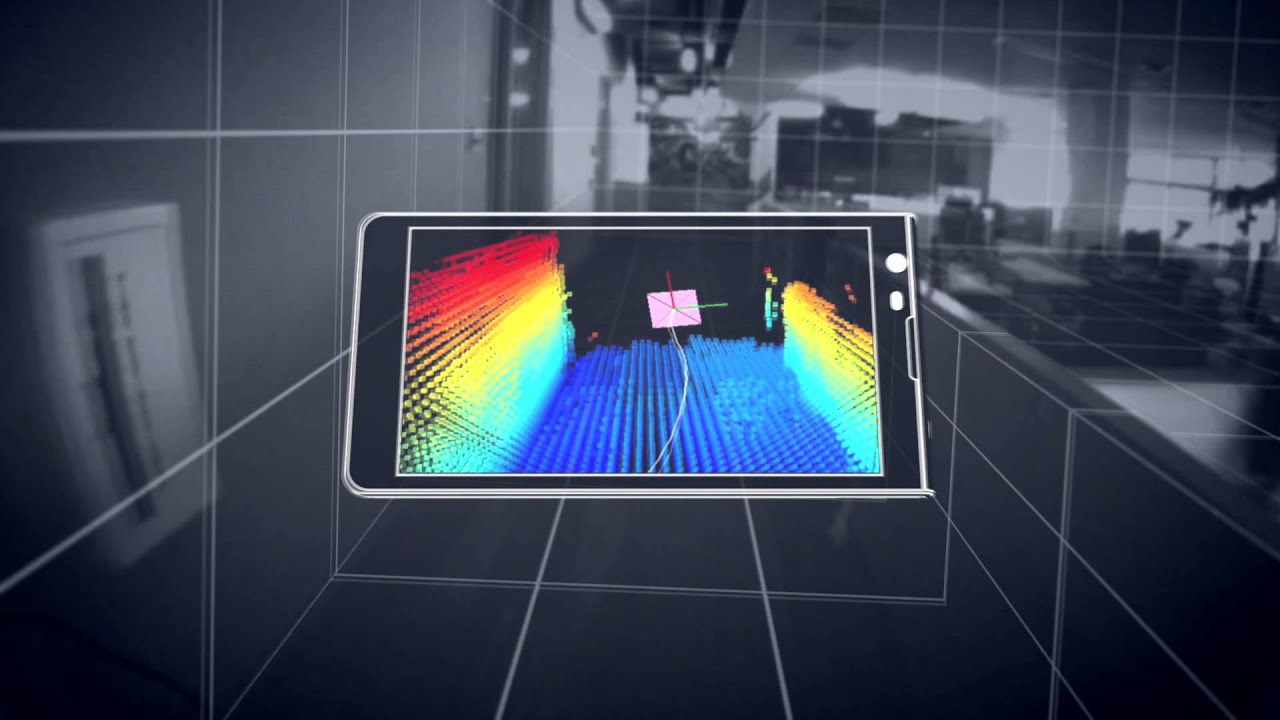

When we were at the

ALS (read about it here), we scanned an eggshell and created an STL file with the data. We asked several 3D-printer manufacturers to print the eggshell blown up about a thousand times.

The companies were excited to help out. We had the eggshells printed on, from left to right (starting with the top row): the UP Plus 2, Cube 2, Afinia, Ultimaker 2, Printr Bot Simple Metal (using Microsoft's new slicer), RoBo 3D, MakerBot Dual, Form 1, and a Printr Bot Simple Metal (using Slic3r).

We were very impressed by the results -- they were far better than we could obtain from our old printers.

The

Printrbot Simple metal has the best value for it's price. I recommend using the Microsoft slicer with it because Slic3r isn't the best at closing holes in the data. The Printrbot also has the standard 100 micron resolution.

For the best quality that isn't SLA, I would rank the

Afinia and the

UP Plus 2 at the top. They both have outstanding XY quality and have no excess bridges like the Cube 2. They are very similar in price, with each costing about $1,600. If you want a mid-ranged consumer 3-D printer, I would definitely recommend one of these.

The

Type A machine is almost as good as the Afinia but it creates more bridges. I don' think the bridges would be a problem for less complicated prints, but for something in our experiments, it produced a lesser quality print than similar printers.

The

Form 1 has the best quality. You can only barely see the layers because SLA printer's levels bond more closely together. One downside to the Form 1 is that its post processing takes an extra 30 minutes to finish the job. The post-processing includes dipping it in rubbing alcohol, so it isn't the best for schools (at least yet). The other downsides are its cost ($3299) and supports. The supports leave marks on the bottom of your print but you can scrape them off very easily. Bottom line: if you are looking for stunning quality, it is hard to beat on the consumer market.

Of course, our experiment was not perfect. We did not always control for slicing software, type of filament, etc. but we think it gave us some pretty interesting results anyway.

On the whole, we were grateful to the manufacturers and very happy with the results of this challenging test. If you are a printer manufacture and would like a full review of your product, email us.

Also, on Thingiverse, you are given the option to "give a shout out." With a click of the button, you can get a tag to print (see image below) to give credit where credit it do. (In Creative Commons land, we call this attribution.)

Also, on Thingiverse, you are given the option to "give a shout out." With a click of the button, you can get a tag to print (see image below) to give credit where credit it do. (In Creative Commons land, we call this attribution.)