There once was a student named Cole, who wanted to design and print an iPad stand. Little did he know just how epic his journey would be...

Definition of ITERATION

1: the action or a process of iterating or repeating; as in a procedure in which repetition of a sequence of operations yields results successively closer to a desired result

__________________________________

Here is a summary of our progress so far:

ATTEMPT #1: iPad stand design using SketchUp (late September)

PROBLEM #1: Those non-manifold edges will get you every time. Despite his best efforts (and those of the

netfabb repair), he could not produce a closed surface model.

SOLUTION #1: Cole redesigned the entire thing on TinkerCAD, which we've found very closed-surface friendly. In fact, the students almost entirely use TinkerCAD for their models, just because it produces such reliable stl files. Despite there being a hold up with

TinkerCAD student accounts....

OUTCOME #1: The model was closed, watertight, and ready to go!

__________________________________

ATTEMPT #2: Redesigned on TinkerCAD. Printed on the Makerbot (Oct 6) after a lengthy gcode generation. At 25% fill, this will be an estimated 17 hour 22 minute print job. I started it early (like 5 am early) in the morning. It seemed to be working quite well. Cole has really pushed our Makerbot to its limits... literally. Since the build took up the entire build plate, part of the raft even hung off the edge of the heated bed.

PROBLEM #2: By 11 am, the filament must have gotten pinched on the spool, since a student yelled out, "Ms. Mytko, something is WRONG with the PRINTER! It is just printing AIR!" Ends up, the feed tube is loose (since the plastic clamps that are supposed to hold it down were broken on day 1 ... I prefer to say they were "over-loved" by the middle school kids). In any case, with the motion of the nozzles, the tube was slipping down until it caused the filament to get caught in the spool. While our temporary solution of rubber bands had apparently been working for short-term prints, it appears this long-term print was going to be an issue. The tube seemed to slip down every couple of hours, causing the filament to pinch.

SOLUTION #2: Cole suggested various solutions (duct tape, print a new clamp, use the other tube, etc), finally settling on the idea of using a binder clip (see diagram below) - it worked! (I liked the diagram me sent to me.)

OUTCOME #2: The tube held, but the filament pinched. It failed after about 8 hours of printing.

__________________________________

__________________________________

ATTEMPT #3: Printed on the Makerbot. Again. (October 8) The feed tube was no longer slipping.

PROBLEM #3: The build plate did not seem to be heating evenly, and one of the back corners was peeling up from the heated bed (the part that said "IPAD"). Plus, 17 hours was a ridiculous amount of time to watch a print job.

SOLUTION #3: For his next print, Cole turned the model around, so that the "IPAD" front was in the opposite corner of the heating platform. He also re-ran the gcode with a 15% fill, to speed up the printing time and allow for reasonable supervision. Now, it will only take 13 hours to print, which is doable considering the number of hours I typically spend in my classroom each day.

OUTCOME #3: Even though this print didn't work either (the filament got pinched again overnight), it was exciting to see the potential.

__________________________________

ATTEMPT #4: Printed on the Makerbot. Again. (October)

PROBLEM #4: Now, the filament kept pinching itself on the roll. If I didn't check on it constantly, even this 13 hours print would fail.

SOLUTION #4: Our other 3D printer, the

Printrbot Jr. v2 came with a

spool coaster, which we borrowed and used to mount the filament spool off the back of the printer. This way, from most angles in the room, you could keep an eye on the white sticker, to check that the filment was, indeed, rotating and not stuck.

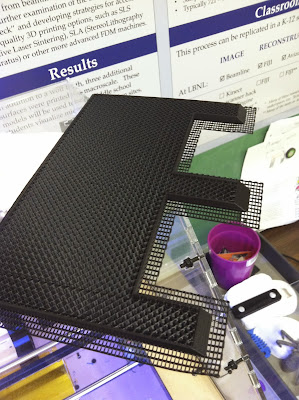

OUTCOME #4: The spool coaster worked great! Every once in a while, either I or a student would look over and realize the coaster has moved. That indicated that it was beginning to pinch, and we had time to fix it before the filament caught in the nozzle and started "printing air." However, it got to be 10pm and night and I was tired of being at school. So I wished the print well and went home. The next morning, the kids and I arrived at school, to find (second picture) that the filament had caught, dragged the spool coaster over, and printed air the last 40% of the stand.

__________________________________

ATTEMPT #5: Printed on the Makerbot. Again. (October 15) This time, we had it. We had fixed the feeding tube slippage issue, found a way to use the spool coaster to keep an eye on the print, and reduced the fill percentage to shorten the print time so that the print wouldn't have to be left unattended overnight. We were ready!

PROBLEM #5: Many hours into the print, it was clear that we did not have enough black filament to finish the print. ARGGGHGH!

ATTEMPTED SOLUTION #5: We thought that maybe we could load new filament of a different color while it was printing. This was not a brilliant idea, but

this guy's blog post made it sound easy!

OUTCOME #5: Yeah, it didn't quite work out. The filament broke off in the extruder, and I had to

clear the filament jam, which wasn't pretty. To clear the jam, the platform had been moved, and afterwards, I tried to return the platform right where it left off. Then I deleted the previous gcode to run what I thought was just the code from where it left off. Ends up you just can't delete the header like that. So, I put the header back and deleted just what I thought was the lines of code for the layers that had already need printed. That was an imperfect adventure. After much experimentation with adding and subtracting lines of gcode, resuming the print was, at best, like trying to ice a cake wearing a blindfold. I learned a lot in the process, but unfortunately did not make a successful print.

__________________________________

ATTEMPT #6: Printed on the Makerbot. Again. (early November) We have a solid feeder tube, reduced fill gcode, rotated design, spool coaster and a recently-received new roll of black filament. Here we go!

PROBLEM #6: With all of the moving around (

Mini-Maker Faire &

Discovery Days) where we took the Makerbot on the road, our printer bed was not quite level. Therefore, the plastic was not sticking effectively to the heated bed.

SOLUTION #6: I tried to level the print bed on the fly while it was printing. Not so effective. Especially when I was distracted by students before the raft made it to the right side, and therefore it was only really partially leveled.

OUTCOME #6: Print job cancelled early in the print due to excessive peeling.

__________________________________

CURRENT STATUS:

We will try it again, since I am curious to see how far we can push our printer. Overall, we've all learned a lot in the process. We also have a revised, much cleaner, school-mascot inspired solution for our broken feeder tube clamps.

Plus a set of really sweet business card holders?

More to come. Stay tuned.