So, I learned today that Minecraft has a 3D builder included, and apparently it exports to .stl. I'm not even sure how my student did it, but perhaps this blog post might give me some insight.

I *do* know that I had one ecstatic kid jumping around my room when it came of the print bed. THAT is the magic of 3D design and printing. The design came out of his head, through the computer, out the nozzle and into his hands. Sweet.

A blog intended for, and often written by, my middle school students, as well as anyone interested in the fascinating potential of 3D printing and the process of getting there. Since our blog's start in 2013, we've expanded our content a bit to incorporate our other middle school making. Click the "Our BPC Story" blog label to learn more about our Maker Club journey.

Saturday, April 20, 2013

Print Shift Magazine Released by Dezeen

Earlier this week, architecture and design blog Dezeen announced that they have released Print Shift, a 56-page, print-on-demand magazine in collaboration with publisher Blurb. The magazine "explores advances in 3D printing across a range of topics including fashion, food, design, architecture and even weaponry and archaeology."

As part of the project, they produced this short movie, highlighting "three of the world's leading 3D-printing pioneers." You can read more about the project here.

I've already ordered my copy. :) It sounds like it will be a slightly fancier compliment to my currently-owned and well-loved copy of Make: Ultimate Guide to 3D Printing.

As part of the project, they produced this short movie, highlighting "three of the world's leading 3D-printing pioneers." You can read more about the project here.

Friday, April 19, 2013

Chicago's "The 3D Printer Experience" Opens Monday!

3D printing will soon become even more accessible in Chicago at "The 3D Printer Experience," the "only retail and interactive store of its kind in the Midwest." Located at 316 N. Clark Street in Chicago, it is set to open next Monday, April 22, 2013.

Read more about the opening on this Fox news page (I know, I know) or the store's website.

I will be sure to visit next time I am in town! I am just excited to meet their printers!

With over twenty 3D printers in-house and exciting new applications for you to play with, we’re here to introduce you to a very bright future of personal, desktop manufacturing. We are dedicated to helping you down a new path of greater creativity and freedom.

Read more about the opening on this Fox news page (I know, I know) or the store's website.

I will be sure to visit next time I am in town! I am just excited to meet their printers!

Thursday, April 18, 2013

What Will Be the Impact of 3D Printing in Education?

I'm not sure we know yet. I'm waiting to see if it is merely a fad, or the next major disruptive technology. Right now, it's fun to print sharks and whistles, but I'm looking forward to learning ways to integrate the machine into meaningful curriculum. My summer work will involve 3D imaging and printing at a research lab, and I look forward to bringing back what I learn to the classroom.

According to an April 10, 2013 EdTech Magazine article,

According to an April 10, 2013 EdTech Magazine article,

It’s still largely unclear how long it will take for 3D printing to achieve widespread adoption in K–12 schools. The most recent Horizon report for K–12 education, a collaboration between EDUCAUSE and the New Media Consortium, said the technology isn’t likely to be mainstream for at least another four years. (emphasis mine)

Stay tuned.

Tuesday, April 16, 2013

Whistle-Blower

Today's print - Whistle by Zaggo. Pretty cool - the bead prints inside and is easily dislodged afterwards with a paperclip. (In fact, before this print, I hadn't given much thought to how whistles work.)

Monday, April 15, 2013

A Helmet, Our First 2+ Hours Print

Finally, after a couple of false starts, we printed our biggest print job yet - a Halo helmet downloaded to SketchUp and converted to STL. (Not my idea, I assure you.) We learned a lot.

|

| Building up with its support material |

|

| 12 hours, 44 mins |

|

| Finished product |

Sunday, April 14, 2013

Bungle #1 - Filament Jam

So, today (yes, Saturday), we were printing some sort of helmet for a kid's project. We were successful in converting the file from SketchUp to stl and printed a small one (using our first "support material") to test the design. We then scaled the item up, set it to a 40% fill, and let it run. The print was scheduled to take 13 hours. (sigh) No problem, I have papers to grade. The students went home about 2 hours into the print, and I stayed and worked. About 5.5 hours into the print, my ears picked up a change in the rhythm of the printer (which is rather soothing, btw). Upon investigation, it ends up the plastic was no longer coming out of the extruder, even though the build was still in progress. Puzzled, I looked at the gcode, and checked the nozzles.... and finally discovered that the filament had come off its spindle, wrapped around the axle, and basically, strangled it to a complete stop. When I pulled it loose, it looked something like this:

So, today (yes, Saturday), we were printing some sort of helmet for a kid's project. We were successful in converting the file from SketchUp to stl and printed a small one (using our first "support material") to test the design. We then scaled the item up, set it to a 40% fill, and let it run. The print was scheduled to take 13 hours. (sigh) No problem, I have papers to grade. The students went home about 2 hours into the print, and I stayed and worked. About 5.5 hours into the print, my ears picked up a change in the rhythm of the printer (which is rather soothing, btw). Upon investigation, it ends up the plastic was no longer coming out of the extruder, even though the build was still in progress. Puzzled, I looked at the gcode, and checked the nozzles.... and finally discovered that the filament had come off its spindle, wrapped around the axle, and basically, strangled it to a complete stop. When I pulled it loose, it looked something like this:Maybe it has something to do with the shoddy tube clamps on the back of my machine (pictured below). The day our Makerbot arrived, the clamps on the lefthand side (in pic) were snapped. The kids claim it "came that way." I am not sure the kids didn't make it that way in their enthusiastic unpacking. In any case, it has been an adventure, as the left pictured tube (for right extruder) often slips and the filament gets pinched. To date, our best solution has been this rubber band set-up. However, it is clear that it is not suitable for a 13 hour print job, and needs more frequent monitoring.

I removed the filament, reloaded the spindle and was set to try again. All 13 hours of it. But the filament wouldn't extrude. Additional investigation made it clear there was likely a bit of broken filament jamming the opening to the nozzle.

So, I used the Makerbot Troubleshooting guide and found this video on how to clear a filament jam. I am grateful for the visual support!

Egads! I am not a tinkerer by nature, and I was rather terrified to disassemble my $2000 machine.... I debated waiting until Monday and asking one of my students to do it (they are fearless), but I decided I'd have to learn sometime.

I will have to admit, however, that it was rather satisfying to find and remove that stubborn little piece of broken filament!

Afterwards, I printed a nice, 5 min guitar pick (from Thingiverse) just to see that it was all working once again. Phew, first crisis averted.

Accessorizing Our MakerBot

Making progress... just purchased my final accessory. This 3mm (1/8") Acrylic Hood and Window Kit" advertises with the phrasing "Stabilize Temperature. Keep Curious Hands Out." - totally targeted to my old drafty school, full of kids who fiddle with everything!

Anyway, so far, so good. We installed the sides without handles, and that front panel with handles, so it is easily removable. The window set does appear to be stabilizing the temperature and it definitely is keeping curious hands (and dirt!) out.

Anyway, so far, so good. We installed the sides without handles, and that front panel with handles, so it is easily removable. The window set does appear to be stabilizing the temperature and it definitely is keeping curious hands (and dirt!) out.

Saturday, April 13, 2013

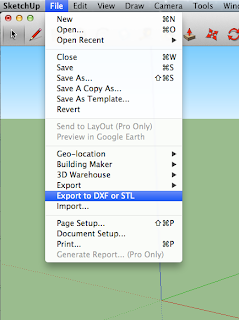

Converting SketchUp to STL Files

This weekend, we were hoping to convert our first SketchUp (SKP) files to STL. There are a lot of options out there, but this is the one we got to work.

We are using a Mac OS (10.8.3) and SketchUp version 8.0.15.157. After many attempts, this blog provided the solution that worked for us.

I am not clear if we have a "Sketchup 8 maintenance release 2 or later," but I do know that when we downloaded the .rbz file and tried to install it via the install extensions button under Sketchup >> Perferences >> Extensions, we continually got an error message upon restart.

However, when I downloaded the Sketchup to DXF or STL plugin - skp_to_dxf.rb ( Sketchup versions 6, 7 or 8) and dropped it in the sketchup plugins folder ( /Library/Application Support/Google SketchUp [VERSION]/SketchUp/Plugins) then restarted SketchUp, this plugin worked fine.

However, when I downloaded the Sketchup to DXF or STL plugin - skp_to_dxf.rb ( Sketchup versions 6, 7 or 8) and dropped it in the sketchup plugins folder ( /Library/Application Support/Google SketchUp [VERSION]/SketchUp/Plugins) then restarted SketchUp, this plugin worked fine.

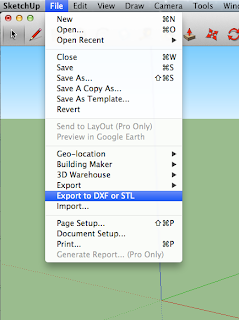

Now, "Export to DXF or STL" is in the drop-down File menu.

Pop-up 1: Set "Export Unit" to "millimeters"

Pop-up 2: Set "Export to DXF" to "stl"

Once we opened it up in Replicator G, we were set!

We are using a Mac OS (10.8.3) and SketchUp version 8.0.15.157. After many attempts, this blog provided the solution that worked for us.

I am not clear if we have a "Sketchup 8 maintenance release 2 or later," but I do know that when we downloaded the .rbz file and tried to install it via the install extensions button under Sketchup >> Perferences >> Extensions, we continually got an error message upon restart.

However, when I downloaded the Sketchup to DXF or STL plugin - skp_to_dxf.rb ( Sketchup versions 6, 7 or 8) and dropped it in the sketchup plugins folder ( /Library/Application Support/Google SketchUp [VERSION]/SketchUp/Plugins) then restarted SketchUp, this plugin worked fine.

However, when I downloaded the Sketchup to DXF or STL plugin - skp_to_dxf.rb ( Sketchup versions 6, 7 or 8) and dropped it in the sketchup plugins folder ( /Library/Application Support/Google SketchUp [VERSION]/SketchUp/Plugins) then restarted SketchUp, this plugin worked fine. Now, "Export to DXF or STL" is in the drop-down File menu.

Pop-up 1: Set "Export Unit" to "millimeters"

Pop-up 2: Set "Export to DXF" to "stl"

Once we opened it up in Replicator G, we were set!

Using Support Material

Today, some students wanted to print a helmet from a design they downloaded on SketchUp (the printing of which is of questionably copyright-legality, but I digress). This print gave us the opportunity to learn about acceleration, which "allows Replicator users to speed up their prints from the previous 40/55 mm/s default extrusion and travel speeds to a much snappier 80/150 mm/s." (source) After a failed test print, we noticed that the model was balanced on a single point. This, of course, made it impossible to print the way we have been printing.

This gave us the chance to learn about support material.

And, here is the finished product, (1) embedded in its support material:

(2) Removing the support material:

(2) Removing the support material:

(3) Final helmet with discarded support material:

Now it is time to scale up. It's gonna be a big one!

This gave us the chance to learn about support material.

And, here is the finished product, (1) embedded in its support material:

(2) Removing the support material:

(2) Removing the support material:(3) Final helmet with discarded support material:

Now it is time to scale up. It's gonna be a big one!

Subscribe to:

Posts (Atom)